Battery Technology

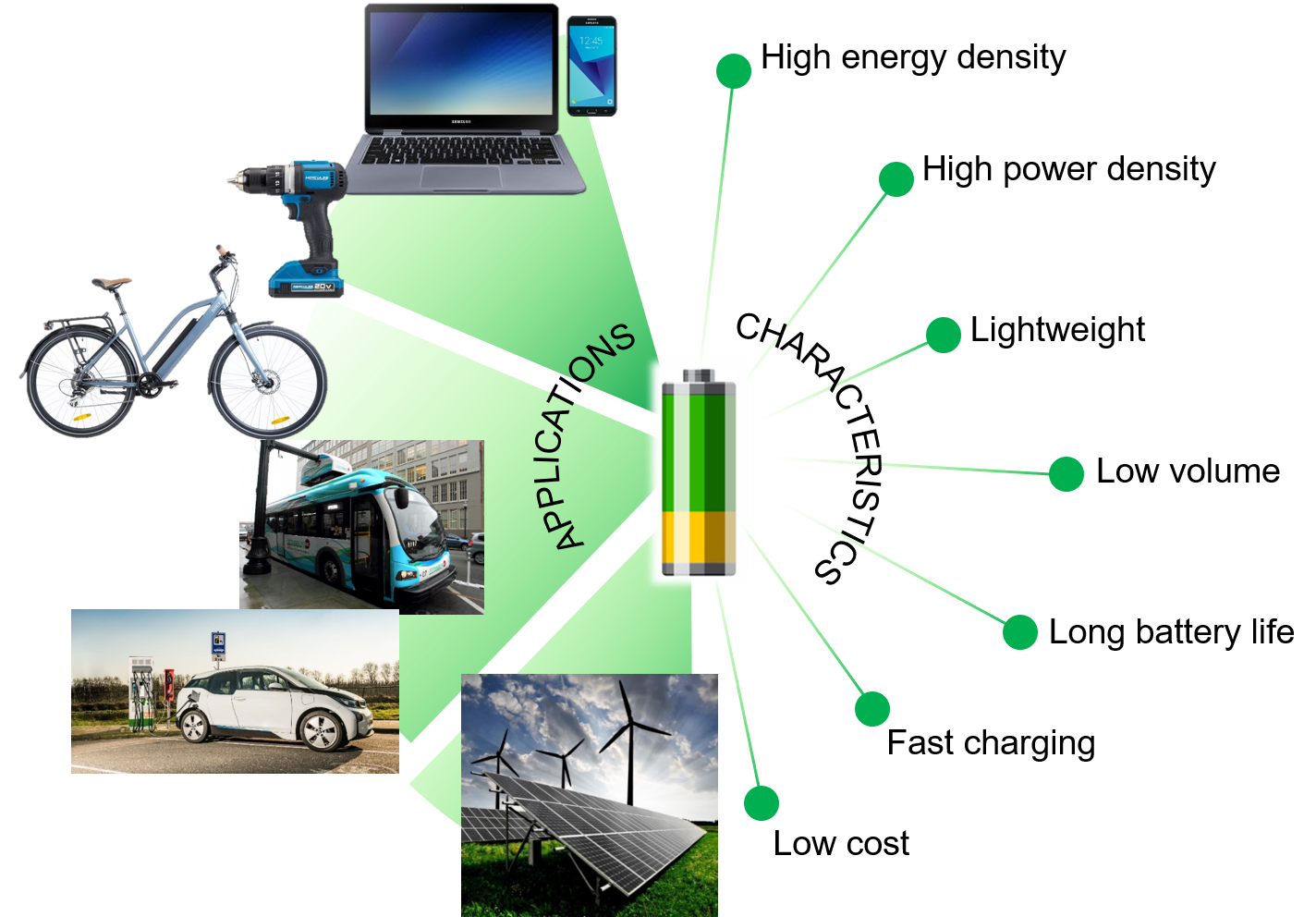

The global energy demand is increasing and finding new sustainable energy alternatives to fossil fuels is now critically important. As non-continuous sources such as solar and wind power play a larger role in our energy production, the development of effective and sustainable energy storage systems is imperative. Our group is developing novel and sustainable carbon materials to be used in key energy storage technologies such as Na-ion batteries, Na-ion capacitors and mixed-ion systems.

Rechargeable lithium-ion batteries have reformed the portable electronic industry, due to their superior energy density (they can store 2-3 times more energy per unit weight and volume in comparison with conventional rechargeable batteries). Typically, a lithium-ion battery consists of two electrodes separated by an electrolyte which can conduct ions but not electrons. On charging, lithium ions travel from the positive electrode (cathode) to the negative terminal (anode), and the electrons simultaneously pass around the external circuit, creating a flow of current. The reverse occurs during cell discharge.

Graphite is widely used as an anode material for lithium-ion batteries. Lithium ions insert into the interlayer spaces to form LiC6, which is equivalent to a theoretical capacity of 372 mAh g‑1. Typically, layered metal oxides of cobalt, manganese or Ni are used for the cathode.

Whilst lithium-ion batteries are an established technology which have been extensively developed, there is concern that the lithium reserves in the Earth are insufficient to satisfy our increasing global energy demands. Furthermore, the resources are concentrated in geographically and politically limited areas, and therefore the search for suitable alternatives is becoming increasingly urgent.

Sodium, another s-block alkali metal, shares similar chemical properties with lithium, and sodium-ion batteries have shown potential as a cost-effective successor to lithium-ion batteries for large-scale, low cost electrical energy storage applications. There are many advantages to exploring the sodium-ion alternative: sodium is distributed evenly and abundantly around the globe; aluminium, rather than copper, may be used as the current collector significantly reducing cost; the equivalent sodium electrolytes are far cheaper; and the processing system is identical, meaning that the production of sodium-ion batteries is a ‘drop-in’ technology.

One major drawback, however, is that graphite, the standard anode material in lithium-ion technology, shows very little capacity for sodium-ion storage (forming the compound NaC64 vs. LiC6). Identifying suitable alternative materials is, therefore, of interest to the research community. Another class of carbons, disordered ‘hard’ carbons, are considered promising anode materials and provide good reversible capacity during sodiation/desodiation cycles.

Hard carbons can be produced by solvothermal conversion of biomass and plastic waste, and in our group we are exploring the use of these carbons as anodes for sodium-ion batteries. By altering the precursor and reaction conditions, we aim to produce a wide range of carbons with varying porosity, graphitic structure, heteroatom-doping, as well as composite materials with soft carbons and with other promising anode candidates such as tin and antimony, to test in sodium-ion batteries. Unlike lithium intercalation into graphite, the sodium storage mechanism in hard carbons is still poorly understood, and we are developing advanced in situ characterisation techniques to study the systems in detail. These experiments will also provide insight into the formation of the solid electrolyte interphase (SEI), and the origins of performance degradation after prolonged cycling and at high current densities. Of course, the anode is not the only component of interest; we have also developed an all-carbon sodium-ion hybrid capacitor, in which the anode, cathode and separator are derived from cellulose precursors.